Wing repairs

While the paint is drying on the hull, I’m getting on with the other stuff. As you may have seen in a previous post, the hiking wings were in a very bad state with severe corrosion. Rather than build a new set of wings, I decided that they could be salvaged, so out came the MAP gas and the aluminium brazing rods.

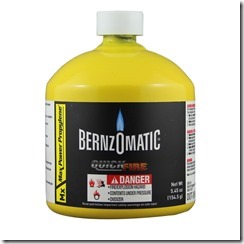

For aluminium brazing you need to be able to get the work up to about 400degC, which is pretty hot! This little unit is great for small jobs but it did struggle to get the tubes up to temperature because the heat so easily dissipates on such a big structure. I could really have done with more grunt, but we got there in the end.

Where the holes were small enough, I just brazed them closed. For the large holes, I made reinforcing patches from Laser mast tubing. I first ground off the anodising around the joints.

I think it’s worked well, as I tested the joints with my weight and they held!

You can buy MAP gas in handy disposable cylinders. MAP gets much hotter than propane.

The welding rods are pre-coated with flux.

Two examples of the repairs needed…

And the finished repairs…

0 Comments:

Post a Comment

Subscribe to Post Comments [Atom]

<< Home